Oil Leak Detection: Advanced Methods, Early Warning Signs, and Professional Solutions

Introduction

Oil leak detection is a critical process for maintaining the performance, safety, and longevity of mechanical systems, industrial equipment, and vehicles. Undetected oil leaks can lead to severe mechanical failures, environmental contamination, and significant financial losses. We focus on delivering a comprehensive and technically accurate guide that addresses oil leak detection from every angle, using proven industry practices and modern diagnostic approaches.

Understanding Oil Leaks in Mechanical and Industrial Systems

Oil leaks usually occur when lubricants escape from sealed systems due to worn gaskets, pressure imbalance, faulty seals, or material degradation over time. These leaks are commonly found in car engines, hydraulic systems, compressors, pipelines, and industrial machinery. When oil leakage is ignored, it can gradually reduce lubrication, increase engine friction, and cause overheating or serious mechanical damage. This is why routine inspection is important, including understanding how to check engine oil in cars, which allows vehicle owners to monitor oil levels, notice unusual drops, and spot possible leaks early. Regular oil checks not only help prevent costly repairs but also improve engine efficiency and extend the overall lifespan of the vehicle.

Common Sources of Oil Leaks

- Worn seals and gaskets

- Cracked hoses and pipelines

- Loose fittings and connectors

- Corrosion in metal components

- Over-pressurized systems

Identifying these sources early allows us to implement corrective actions before leaks escalate into major failures.

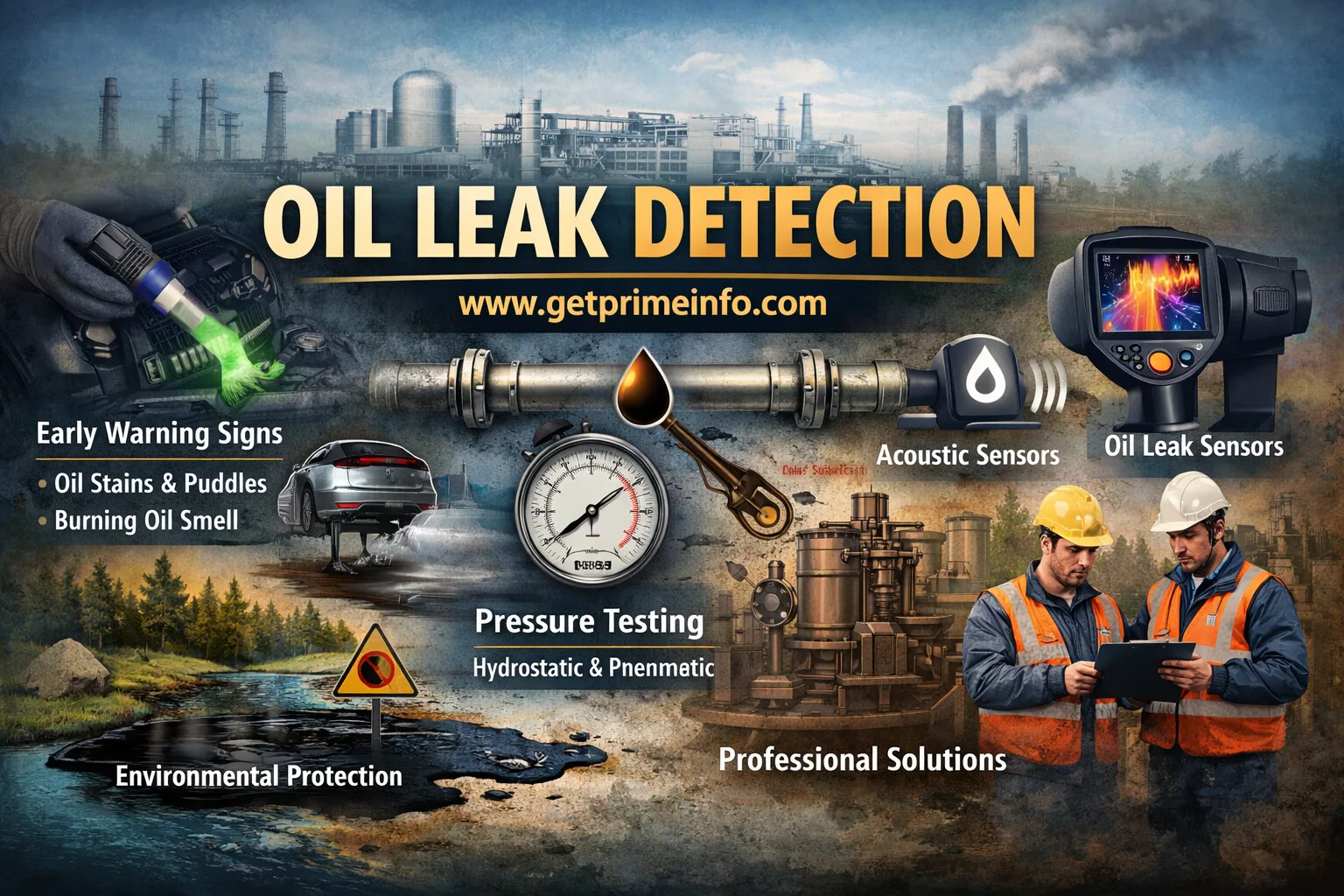

Key Warning Signs of Oil Leaks

Recognizing the early indicators of oil leakage is essential for proactive maintenance. Some of the most common warning signs include:

- Visible oil stains on floors or equipment surfaces

- Burning oil smell during equipment operation

- Decreased oil levels without clear consumption reasons

- Reduced system efficiency and overheating

- Increased vibration or unusual noises

Ignoring these symptoms often results in extensive system damage and costly repairs.

Visual Oil Leak Detection Techniques

Visual inspection remains one of the most effective and widely used methods. Regular inspections help identify leaks before they worsen.

Surface Inspection

We inspect seals, joints, and connection points for visible oil residue, wet spots, or accumulated grime that indicates slow leaks.

Dye-Based Leak Detection

Using UV fluorescent dyes, oil leaks become easily visible under ultraviolet light. This method is especially effective for identifying micro-leaks in complex systems.

Pressure Testing for OLD

Pressure testing is a reliable technique for detecting hidden leaks in sealed systems.

Hydrostatic Pressure Testing

This method involves pressurizing the system with fluid to identify pressure drops that indicate leaks. It is commonly used in pipelines, hydraulic systems, and industrial machinery.

Pneumatic Pressure Testing

Air or inert gas is used to pressurize the system, making it easier to detect leaks through audible signals or pressure changes.

Electronic and Sensor-Based Oil Leak Detection

Modern oil leaks increasingly relies on advanced sensor technologies that provide real-time monitoring and precise diagnostics.

Oil Leak Sensors

These sensors detect the presence of oil outside designated containment areas and trigger automatic alerts for immediate action.

Acoustic Emission Sensors

Acoustic sensors identify leaks by detecting high-frequency sound waves generated by escaping oil under pressure.

Infrared Thermography

Infrared cameras detect temperature variations caused by oil leaks, making this method ideal for high-temperature and inaccessible systems.

Oil Leak Detection in Automotive Systems

Oil leaks in vehicles can compromise engine performance and safety. Automotive OLD focuses on:

- Engine oil systems

- Transmission and gearbox units

- Power steering systems

- Brake hydraulic systems

Common Automotive Leak Points

- Valve cover gaskets

- Oil pan seals

- Crankshaft seals

- Turbocharger oil lines

Timely oil leak detection ensures optimal engine lubrication, reduced emissions, and extended vehicle lifespan.

Industrial OLD Solutions

Industrial environments demand robust OLD strategies due to high operating pressures and continuous workloads.

Pipeline Leak Detection

Advanced pipeline monitoring systems use flow analysis, pressure sensors, and AI-based analytics to detect oil leaks instantly.

Machine Condition Monitoring

By integrating OLD with predictive maintenance systems, we minimize downtime and prevent large-scale failures.

Environmental Impact of Undetected Oil Leaks

Oil leaks pose a serious threat to the environment, contaminating soil, groundwater, and water bodies. Regulatory agencies enforce strict compliance standards, making effective OLD a necessity.

Environmental Protection Benefits

- Reduced pollution and cleanup costs

- Compliance with environmental regulations

- Improved corporate responsibility and sustainability

Proactive oil leak detection protects both operational assets and the surrounding ecosystem.

Preventive Maintenance and Oil Leak Prevention

Prevention is always more cost-effective than repair. Implementing structured maintenance programs significantly reduces the risk of oil leaks.

Best Preventive Practices

- Routine inspection schedules

- Timely replacement of seals and gaskets

- Proper torque application on fittings

- Monitoring operating pressures and temperatures

- Using high-quality lubricants

Preventive maintenance ensures consistent performance and minimizes unexpected downtime.

Professional Services

Professional oil leak detection services offer specialized equipment, expert analysis, and accurate diagnostics. These services are ideal for complex systems where in-house detection methods may fall short.

Benefits of Professional Services

- High-precision detection tools

- Comprehensive system evaluation

- Faster leak identification and resolution

- Long-term cost savings

Engaging professionals ensures reliable detection and effective remediation strategies.

Future Trends

Technological advancements continue to reshape OLD methodologies.

Emerging Innovations

- AI-driven predictive analytics

- Smart IoT-based leak sensors

- Automated shutdown systems

- Remote monitoring platforms

These innovations improve detection accuracy, reduce response time, and enhance overall system safety.

Conclusion

Oil leak detection is an indispensable component of modern maintenance and operational safety strategies. By combining visual inspections, pressure testing, sensor-based technologies, and preventive maintenance, we achieve reliable and efficient leak management. Early detection not only prevents mechanical failures but also safeguards the environment and reduces operational costs. Implementing advanced OLD solutions ensures long-term system integrity and uninterrupted performance.