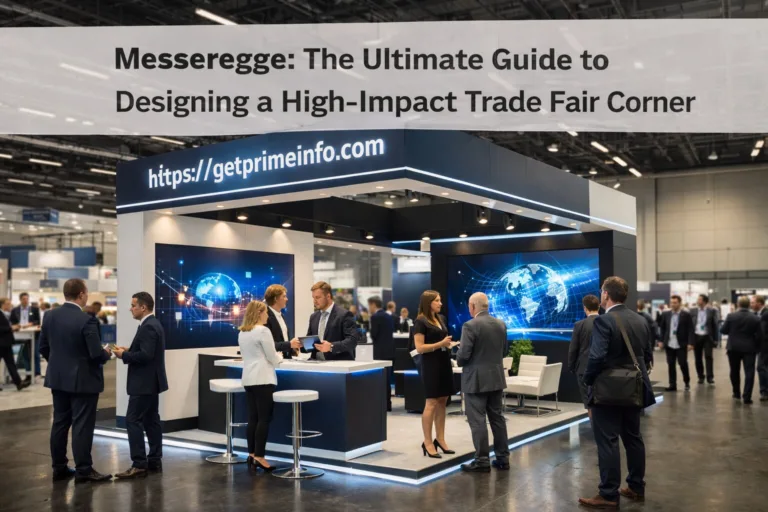

Pappedeckel: Meaning, Material, Uses, in Modern Packaging 2026

Have you ever held a sturdy cardboard box and wondered what makes it so reliable? That seemingly simple material—strong enough to protect your online orders yet light enough to carry effortlessly—is often referred to in German as Pappedeckel. While the word might sound unfamiliar to some, the material itself is everywhere. From shipping boxes and cereal cartons to protective packaging inserts, Pappedeckel plays a crucial yet often overlooked role in modern life.

In today’s packaging-driven economy, materials matter more than ever. Businesses are under pressure to reduce waste, lower carbon emissions, and deliver products safely. Consumers demand sustainability without sacrificing quality. And governments worldwide are pushing for eco-friendly alternatives to plastic. In this evolving landscape, Pappedeckel stands at the center of the conversation.

This article delves into what Pappedeckel truly means, its manufacturing process, applications, and why it has become a vital component of modern packaging solutions. We’ll explore its material composition, environmental impact, advantages over other packaging options, and the innovations shaping its future.

By the end, you’ll see that Pappedeckel isn’t just cardboard. It’s a material that bridges functionality, affordability, and sustainability—three pillars of today’s packaging industry.

Table of Contents

What Does Pappedeckel Mean?

The term Pappedeckel originates from the German language. Literally translated, “Pappe” means cardboard or paperboard, and “Deckel” means lid or cover. Together, the word often refers to a sturdy cardboard piece, lid, or board made from compressed paper fibers. While in everyday German usage it can casually refer to a cardboard cover, in industrial contexts it generally signifies thick paperboard material used for packaging and structural purposes.

Unlike thin paper sheets, Pappedeckel represents a more robust material. It is typically denser, layered, and engineered for strength. In English, similar materials are referred to as cardboard, paperboard, or fiberboard, depending on thickness and construction. However, the German term carries a broader meaning that can include various grades and types.

Regionally, Pappedeckel may be used informally to describe simple cardboard coasters, box lids, or protective sheets. But in manufacturing and packaging industries, it refers to high-quality board materials used for protective and retail packaging.

Understanding the meaning is important because it reflects how language shapes industry standards. What one region calls cardboard may encompass multiple technical categories elsewhere. Pappedeckel, therefore, isn’t just a word—it represents a classification of engineered paper-based materials designed for durability and practicality.

The growing global exchange of goods has increased the visibility of such terms. As European packaging standards influence global markets, terminology like Pappedeckel becomes more recognized in international trade discussions.

In short, Pappedeckel means more than “cardboard lid.” It symbolizes a versatile, durable paper-based material essential to packaging and product protection worldwide.

History and Evolution

To understand the importance of Pappedeckel today, we need to look backward. Cardboard-like materials date back centuries, with early paperboard appearing in China shortly after paper was invented. However, industrial-scale production began much later, during the 19th century, when packaging demands increased due to trade expansion and industrialization.

The development of corrugated cardboard in the 1800s revolutionized packaging. Suddenly, products could be transported safely over long distances without excessive weight. Germany, known for engineering and manufacturing excellence, adopted and refined paperboard technologies, leading to widespread use of Pappedeckel in various industries.

During the 20th century, two world wars and economic shifts pushed industries to find affordable, lightweight, and efficient packaging materials. Metal and wood were often expensive or scarce. Paperboard became a practical alternative. Factories improved pulping processes, layering techniques, and structural reinforcement methods.

The rise of supermarkets in the mid-20th century further boosted demand. Retail packaging required materials that were both protective and printable. Pappedeckel fit perfectly—it offered a smooth surface for branding and graphics while maintaining structural integrity.

In the 21st century, environmental concerns reshaped the industry again. With plastic pollution becoming a global issue, attention returned to paper-based materials. Recycling technologies advanced, making Pappedeckel more sustainable than ever before.

Today, modern Pappedeckel is not just pressed paper. It is engineered for specific purposes—moisture resistance, high load-bearing capacity, or premium packaging aesthetics. Its evolution mirrors society’s shifting priorities: from basic protection to sustainability and innovation.

Composition and Material Structure

At its core, Pappedeckel is made from paper fibers derived primarily from wood pulp. But don’t let that simplicity fool you. The engineering behind it is surprisingly sophisticated.

The production process begins with pulping. Wood chips are processed mechanically or chemically to separate cellulose fibers. These fibers are then mixed with water to form a slurry. Depending on the desired strength and texture, recycled paper fibers may also be added.

Once prepared, the pulp is spread into layers and pressed under high pressure. This layering technique significantly increases strength. Think of it like stacking thin sheets to create a thick, solid board. Each layer bonds tightly with the next, forming a dense structure.

There are two main structural types:

- Solid Paperboard – Made from multiple compressed layers for rigidity.

- Corrugated Board – Features a fluted inner layer between flat liners for enhanced shock absorption.

Additives may be included to improve properties such as:

- Moisture resistance

- Fire retardancy

- Surface smoothness for printing

The thickness can range from thin carton board (used for cereal boxes) to heavy-duty industrial board (used for shipping and protective packaging).

What makes Pappedeckel particularly valuable is its balance. It’s strong but lightweight. It’s rigid yet slightly flexible. It can absorb impact without breaking easily. That combination makes it ideal for packaging applications where both protection and cost-efficiency matter.

Modern advancements also include coatings that enhance water resistance while maintaining recyclability. As sustainability becomes a driving force, manufacturers continuously refine the composition to reduce environmental impact without compromising performance.

Types of Pappedeckel Materials

Not all Pappedeckel is created equal. Just like there are different grades of steel or plastic, paperboard materials vary significantly depending on purpose and performance requirements.

One common type is solid bleached board (SBB). This material is made from virgin wood pulp and offers a clean, white surface ideal for premium packaging. Luxury brands often use it for cosmetics, electronics, and high-end retail packaging because of its excellent print quality.

Another popular type is folding boxboard (FBB). It combines layers of mechanical pulp and chemical pulp to achieve strength while remaining lightweight. This makes it perfect for food packaging, pharmaceuticals, and consumer goods.

Corrugated Pappedeckel is perhaps the most recognizable. It includes a fluted inner layer sandwiched between linerboards. The fluting acts like tiny arches, providing cushioning and shock absorption. This type dominates shipping and e-commerce packaging.

There’s also recycled board, made entirely from reclaimed paper materials. While slightly less pristine in appearance, it is highly sustainable and widely used for industrial packaging.

Coated variants provide extra durability and moisture resistance, while uncoated boards offer breathability and recyclability.

Each type serves a unique role. Choosing the right Pappedeckel depends on factors like weight requirements, environmental exposure, branding needs, and cost considerations.

The diversity of options ensures that this material remains adaptable across industries. Whether protecting fragile electronics or presenting luxury cosmetics, there’s a type designed for the job.

Manufacturing Process of Pappedeckel

The manufacturing process of Pappedeckel may look simple from the outside—trees go in, cardboard comes out—but the reality is far more technical and fascinating. Behind every sturdy board lies a carefully controlled sequence of engineering steps designed to balance strength, flexibility, and sustainability.

It all begins with raw material preparation. Wood logs are debarked and chipped into small pieces. These chips are then processed into pulp using either mechanical grinding or chemical treatment. Mechanical pulping preserves more wood fibers but consumes more energy, while chemical pulping removes lignin, producing stronger and cleaner fibers. The choice depends on the final application of the Pappedeckel.

Next comes the pulp mixing stage. The fibers are blended with water to create a slurry. At this stage, manufacturers may add recycled paper fibers, strengthening agents, or special additives to improve moisture resistance or surface smoothness. This mixture determines the board’s final characteristics.

The slurry then moves to a paper machine, where it is evenly spread onto a moving screen. Water drains away, leaving a mat of interwoven fibers. This mat passes through heavy rollers that press and compress the layers, forming a dense sheet. For thicker boards, multiple layers are stacked and bonded together under pressure.

After pressing, the material enters the drying phase. Heated cylinders remove remaining moisture, stabilizing the structure. Precise temperature control ensures uniform strength and prevents warping.

Finally, the board undergoes finishing processes, including cutting, coating, laminating, or printing. Corrugated Pappedeckel is created by shaping one layer into flutes and gluing it between flat liners.

Modern factories emphasize sustainability by recycling water, reusing waste fibers, and optimizing energy consumption. The result? A material that feels simple but is backed by sophisticated technology and environmental responsibility.

Key Properties and Characteristics

What makes Pappedeckel so widely used across industries? The answer lies in its unique blend of properties. It’s not just cardboard—it’s engineered performance.

First and foremost is the strength-to-weight ratio. Pappedeckel offers impressive durability while remaining lightweight. This is crucial in shipping, where every gram affects transportation costs. Corrugated structures, in particular, distribute weight efficiently, preventing collapse under pressure.

Another essential characteristic is flexibility with rigidity. While the board is firm enough to maintain shape, it still allows folding and shaping. That’s why it works perfectly for boxes, cartons, and inserts. It bends without breaking—a small but powerful advantage.

Printability is another standout feature. The surface of many Pappedeckel types is smooth and receptive to inks, making it ideal for branding and marketing. High-quality graphics can be applied using digital, offset, or flexographic printing. For retail packaging, this visual appeal is critical.

Sustainability adds another layer of value. Pappedeckel is:

- Recyclable

- Biodegradable

- Often made from renewable resources

Additionally, it offers decent thermal insulation, which is helpful in food packaging and temperature-sensitive shipments.

Let’s summarize its core characteristics:

| Property | Benefit |

| Lightweight | Reduces shipping costs |

| Durable | Protects products effectively |

| Printable | Enhances branding |

| Recyclable | Supports sustainability goals |

| Customizable | Adaptable to various industries |

These combined traits explain why Pappedeckel remains a top choice in modern packaging.

Common Uses of Pappedeckel

Look around your home or workplace. Chances are, Pappedeckel is everywhere. It quietly supports industries that power daily life.

The most obvious use is in shipping and e-commerce packaging. Online shopping has exploded globally, and corrugated Pappedeckel boxes protect everything from electronics to clothing during transit. Without it, fragile goods would rarely survive delivery.

In the food industry, folding boxboard is used for cereal boxes, frozen food cartons, pizza boxes, and beverage carriers. It provides structure while allowing attractive branding. Some variants are treated to resist grease and moisture.

Retail heavily relies on Pappedeckel for display packaging. Cosmetic boxes, pharmaceutical cartons, and luxury product packaging often use high-quality paperboard with premium finishes. It’s not just about protection—it’s about presentation.

Industrial applications include:

- Protective corner guards

- Layer pads for pallets

- Heavy-duty shipping containers

- Book covers and file folders

Even creative industries use it for crafts, prototypes, and architectural models.

Why is it so versatile? It can be cut, folded, glued, printed, and laminated with ease. It adapts to small boutique businesses and massive logistics operations alike.

In short, Pappedeckel isn’t confined to one sector. It’s a universal packaging solution woven into modern commerce.

Role in Modern Packaging Solutions

Modern packaging isn’t just about wrapping products—it’s about solving problems. It must protect, inform, promote, and minimize environmental harm. Pappedeckel rises to this challenge remarkably well.

One major role is product protection. The layered design of corrugated boards absorbs shock during shipping. Think of it like a built-in cushion. The fluted structure acts as a buffer against impact.

Customization is another strength. Brands can design boxes tailored to specific product dimensions, reducing empty space and minimizing material waste. This is especially important in e-commerce, where optimized packaging lowers shipping costs.

Pappedeckel also supports branding and marketing strategies. Eye-catching graphics, embossing, and matte or gloss finishes turn simple boxes into powerful marketing tools. Packaging often creates the first impression—and first impressions matter.

Sustainability is perhaps its biggest contribution to modern solutions. As companies shift away from plastic, paper-based materials provide an eco-conscious alternative. Many businesses now proudly advertise “plastic-free packaging,” with Pappedeckel at the core.

Additionally, it integrates with automation systems in warehouses. Boxes can be quickly assembled, sealed, labeled, and stacked using machines, increasing efficiency.

In a fast-moving global market, Pappedeckel balances performance, cost, and environmental responsibility. That balance is what keeps it relevant in modern packaging strategies.

Environmental Impact and Sustainability

Sustainability isn’t a trend—it’s a necessity. Pappedeckel stands out because it aligns with environmental goals better than many alternative materials.

First, it’s made from renewable resources. Trees used in pulp production are often sourced from managed forests, where replanting ensures long-term sustainability. Responsible forestry practices play a key role.

Second, recycling rates for paperboard are among the highest of any material globally. Used Pappedeckel can be collected, pulped, and reused multiple times. This circular system reduces waste and conserves raw materials.

Third, it’s biodegradable. Unlike plastic, which can persist for centuries, paper-based materials break down naturally under proper conditions.

However, sustainability isn’t automatic. Energy use during production and transportation still contributes to carbon emissions. That’s why many manufacturers invest in renewable energy, water recycling systems, and low-emission processes.

Compared to plastic packaging, Pappedeckel generally has:

- Lower long-term environmental impact

- Easier recycling processes

- Reduced microplastic pollution risk

Consumers increasingly prefer eco-friendly packaging, influencing corporate decisions. Brands that adopt sustainable Pappedeckel solutions often gain a competitive advantage.

The environmental importance of Pappedeckel goes beyond recyclability. It represents a shift toward responsible production and consumption patterns in global packaging systems.

Advantages Over Plastic Packaging

The comparison between Pappedeckel and plastic packaging is one of the most discussed topics in sustainability circles. While plastic offers durability and water resistance, Pappedeckel brings advantages that are increasingly hard to ignore.

First, there’s environmental perception and reality. Plastic pollution has become a global crisis, filling oceans and landfills. Pappedeckel, on the other hand, is biodegradable and widely recyclable. This makes it far more acceptable to environmentally conscious consumers.

Second, branding opportunities are stronger with paper-based materials. Printing on Pappedeckel is straightforward and visually appealing. Plastic often requires additional labels or treatments for a similar visual impact.

Cost efficiency is another benefit. While price fluctuates depending on market conditions, large-scale paperboard production is generally competitive. Shipping costs are often lower due to its lightweight nature.

Let’s compare quickly:

| Factor | Pappedeckel | Plastic |

| Recyclability | High | Limited in many regions |

| Biodegradability | Yes | No |

| Print Quality | Excellent | Moderate |

| Environmental Image | Positive | Negative |

Of course, plastic still dominates certain moisture-heavy applications. But ongoing innovation is narrowing that gap.

The shift toward Pappedeckel reflects broader societal change—prioritizing sustainability without compromising functionality.

Challenges and Limitations

As versatile and sustainable as Pappedeckel may be, it isn’t perfect. Every material has trade-offs, and understanding the limitations of Pappedeckel is just as important as recognizing its strengths. After all, informed decisions lead to better packaging solutions.

One of the most common challenges is moisture sensitivity. Paper-based materials naturally absorb water. In humid environments or during exposure to rain, untreated Pappedeckel can weaken, warp, or lose structural integrity. This is especially critical in food packaging or long-distance shipping, where environmental conditions vary. While coatings and laminations can improve resistance, they sometimes reduce recyclability.

Another limitation involves load-bearing capacity. Although corrugated Pappedeckel is strong for its weight, it cannot match the durability of certain plastics or metals under extreme stress. Heavy industrial equipment or high-moisture goods may require reinforcement or alternative materials.

There’s also the issue of space efficiency in storage. Flat-packed cardboard saves space, but assembled boxes can occupy significant warehouse volume. Businesses must carefully manage logistics to maintain efficiency.

Production costs can fluctuate depending on pulp prices, energy costs, and global supply chains. When wood pulp demand rises, prices may increase, impacting packaging budgets.

Environmental concerns, while generally favorable, are not entirely absent. Paper manufacturing consumes water and energy. Sustainable forestry and responsible production practices are essential to maintaining its eco-friendly reputation.

Despite these challenges, innovation continues to address many of these limitations. Advanced coatings, hybrid materials, and structural engineering are steadily improving performance. The key isn’t to see these challenges as weaknesses but as areas for improvement and development.

In the end, no packaging material is flawless. The value of Pappedeckel lies in its adaptability and the industry’s commitment to refining it.

Innovations in Pappedeckel Technology

If you think cardboard is old-fashioned, think again. Pappedeckel technology has evolved dramatically in recent years. What once seemed like a simple brown box is now a product of advanced engineering and design innovation.

One major breakthrough is the development of water-resistant and grease-resistant coatings that remain recyclable. Traditionally, adding protective layers reduced eco-friendliness. Today, new bio-based coatings allow packaging to resist moisture while maintaining sustainability standards.

Another innovation is lightweight engineering. Manufacturers now design corrugated flutes and layered structures that use less material while preserving strength. This reduces resource consumption and transportation costs—a win for both business and environment.

Smart packaging integration is also gaining momentum. Imagine a Pappedeckel box with embedded QR codes, NFC chips, or temperature-sensitive indicators. These additions enhance traceability, supply chain transparency, and customer engagement.

Digital printing advancements have transformed branding possibilities. High-resolution, customizable graphics can now be printed directly onto paperboard with minimal setup time. This allows for limited-edition packaging, personalized branding, and rapid design changes.

There’s also a push toward fully circular production systems, where waste materials are reintroduced into the manufacturing process. Closed-loop recycling ensures minimal environmental impact.

Sustainable adhesives, plant-based inks, and biodegradable laminates are further expanding Pappedeckel’s potential.

Innovation keeps the material competitive in a world demanding smarter, greener packaging solutions. Far from being outdated, Pappedeckel is entering a new era—one driven by technology and environmental responsibility.

Economic Importance in Global Markets

Pappedeckel isn’t just a material—it’s a major economic driver. The global paperboard and packaging industry generates billions of dollars annually and supports millions of jobs worldwide.

The rise of e-commerce has significantly increased demand. Every online purchase requires protective packaging, and corrugated board dominates this sector. From small startups to global retail giants, businesses rely on paper-based packaging for safe delivery.

Developing economies also contribute to growth. As urbanization increases and retail markets expand, packaging demand rises. Food distribution, electronics manufacturing, and pharmaceutical industries all depend heavily on reliable paperboard materials.

Export and trade play a central role. Countries with strong forestry resources and advanced manufacturing capabilities often lead production. Germany, the United States, China, and Scandinavian nations are among the key players.

Market trends show consistent growth driven by:

- Sustainable packaging regulations

- Consumer preference for eco-friendly products

- Expansion of global logistics networks

Investment in recycling infrastructure further strengthens the economic cycle. Recycled Pappedeckel reduces raw material costs while supporting environmental goals.

For businesses, switching to paper-based packaging often enhances brand image and customer loyalty. That intangible value translates into measurable financial returns.

In short, Pappedeckel is not just part of packaging—it’s part of the global economy. Its continued relevance ensures stable growth and innovation across industries.

Future of Pappedeckel in the Packaging Industry

What does the future hold for Pappedeckel? If current trends are any indication, its role will only grow stronger.

Sustainability will remain the dominant force shaping the industry. Governments worldwide are introducing stricter regulations on single-use plastics. Businesses are responding by increasing investment in paper-based alternatives. Pappedeckel is positioned at the forefront of this transformation.

The circular economy model will drive innovation. Instead of the traditional “produce-use-dispose” cycle, companies aim for continuous reuse and recycling. Pappedeckel fits naturally into this system due to its recyclability.

Automation and AI-driven manufacturing will improve efficiency. Smart factories can optimize fiber usage, reduce waste, and enhance product consistency.

Another promising area is biotechnology integration. Researchers are exploring ways to strengthen paper fibers using natural enzymes or plant-based reinforcements. These advancements could further close the performance gap between cardboard and plastic.

Customization will also define the future. Consumers expect personalized experiences—even in packaging. Digital printing and flexible design systems will make small-batch production more accessible.

Ultimately, the future of Pappedeckel is about balance—performance, sustainability, and innovation working together. As environmental awareness continues to rise, this humble material may become one of the most important components of modern packaging solutions.

Conclusion

Pappedeckel may seem like a simple piece of cardboard, but its impact reaches far beyond its appearance. From its linguistic roots in German to its central role in global packaging systems, it represents a blend of practicality, sustainability, and innovation.

We explored its meaning, historical evolution, material composition, manufacturing processes, and diverse applications. We examined its strengths, acknowledged its challenges, and looked ahead to future possibilities.

In a world increasingly focused on environmental responsibility, Pappedeckel stands as a practical solution bridging business needs and ecological concerns. It protects products, enhances branding, supports recycling systems, and drives economic growth.

The next time you open a package, take a moment to appreciate the engineering behind it. That sturdy board isn’t just packaging—it’s a symbol of modern industry adapting to a changing world.

FAQs

1. What does Pappedeckel mean in English?

Pappedeckel is a German term that generally refers to cardboard or paperboard material used in packaging and structural applications.

2. Is Pappedeckel environmentally friendly?

Yes, it is recyclable, biodegradable, and often made from renewable resources, making it more sustainable than many plastic alternatives.

3. What industries use Pappedeckel the most?

E-commerce, food packaging, retail, pharmaceuticals, and industrial shipping are major users.

4. Can Pappedeckel replace plastic completely?

While it can replace plastic in many applications, certain moisture-heavy or extreme conditions may still require alternative materials.

5. How is Pappedeckel recycled?

Used paperboard is collected, pulped, cleaned, and reprocessed into new board products, supporting a circular economy.